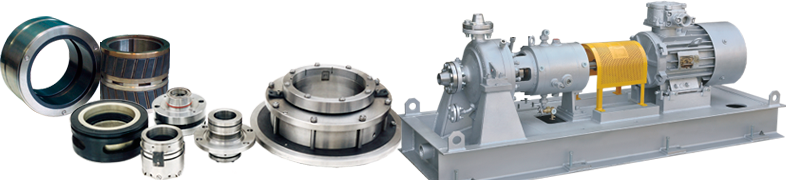

In November 2021, the company R&PC «ANOD» received a batch of dry gas dynamic seals manufactured by EagleBurgmann, operated at Yuzhno-Priobsky GPP LLC, for restoration repairs.

Technical characteristics of seals:

- Type of seals: tandem, unidirectional rotation.

- Shaft diameter, mm: 98.

- Gas temperature, max (°C): -40…. +190.

- Pressure, dynamos. ,MPa: 1,7.

- Pressure, stat., MPa: 7,8.

- Nominal number of compressor rotor revolutions per minute: 13100.

- The material of the friction pair rings: silicon carbide.

- Pumped medium: associated petroleum gas.

The seals were dirty, the rings of the friction pairs had wear. Some metal parts had erosion damage. Polymer sealing rings have lost elasticity. During the repair, the seals were cleaned of dirt. Springs, fasteners, polymer sealing rings were replaced. Damaged metal parts are manufactured again. The rings of the friction pairs were repaired, followed by the application of a diamond-like coating and gas-dynamic grooves (photo 2).

After successful factory tests in December 2021, the seals were transferred to the customer for further operation.